Titanium Etching for Medical Devices

posted 7th July 2021

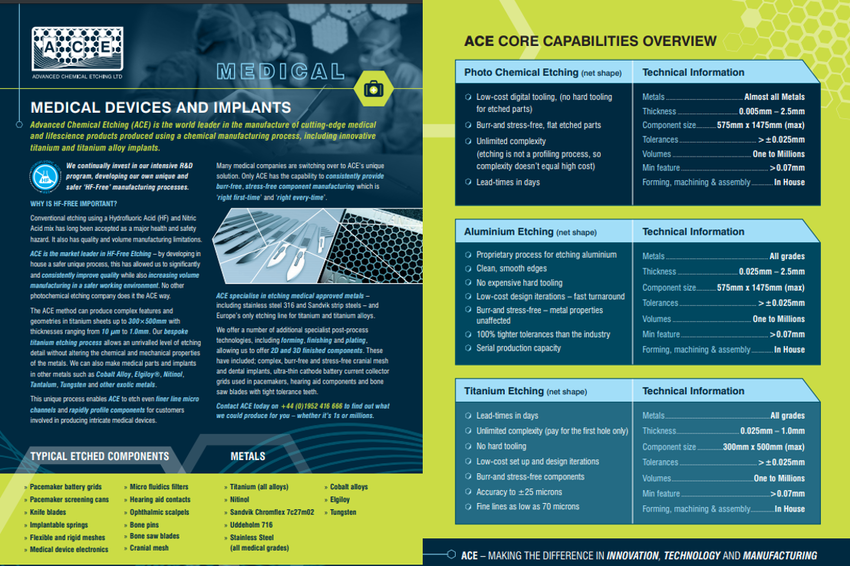

Titanium and titanium-rich alloys have widespread use in medical applications, due to their biocompatibility, corrosion resistance and mechanical strength. Applications include but are certainly not restricted to pacemaker battery grids, bone screws and pins, implantable springs, flexible and rigid meshes, knife blades, hearing aid contacts etc etc.

While titanium itself is a very reactive metal, it exhibits excellent corrosion resistance in practice thanks to its ability to form an insulating or protective oxide layer upon exposure to oxygen.

Stabilising and processing the material using a method known as Photo Etching typically involves the use of Hydrofluoric acid (HF).

However, there are two major issues associated with the use of etching solutions containing HF and nitric acid. HF is a major health and safety hazard. The fluoride ion generated in the process readily penetrates the skin, damaging deep tissue layers and bone. Moreover, both HF and nitric acid tend to attack the photoresist used in the etching process which, ultimately leads to its detachment and therefore the failure of any part.

Photochemical etching is an alternative process that can be used in the manufacture of titanium parts. UK based Advanced Chemical Etching Ltd (ACE) has invested in an intensive R&D programme to develop a non-HF process for the etching of titanium alloys. These R&D efforts have culminated in the development of the TiME process for etching titanium (both alpha and beta) and nickel-titanium alloys. The new process uses a unique chemistry that is safer than conventional HF-based solutions. The process also includes a pre-treatment step to improve photoresist adhesion to the metal, as well as a post-etch treatment process to achieve the required surface finish.

The recent expansion of the company to double its previous size has been driven in part by the success of the new TiME process. ACE has invested in a new etching department, including new staff and state-of-the-art etching, cleaning, measuring and inspection equipment.

Etching can produce complex features and geometries in titanium sheets . Thicknesses ranging from 25 µm to 1.0 mm can be processed using the TiME process. Moreover, the process does not affect the chemical and mechanical properties of the metal.

ACE are at Units 31 – 34, Hortonwood 33, Telford, Shropshire,TF1 7EX

+44(0)1952 416666

info@ace-uk.net