The Electrospinning Company spotlights new sutureless stent coating division

posted 12th December 2022

Biomaterials innovator, The Electrospinning Company has announced the launch of their new sutureless stent coating division, headed up by electrospinning specialist Dr Katrina Moisley.

“The Electrospinning Company has been offering design, development, and manufacturing services to the medical device industry since gaining ISO 13485 certification in 2015”, says Dr Moisley, “We’ve had so many new clients in the last 12 months asking the same question. Can you really electrospin directly onto our stents?”

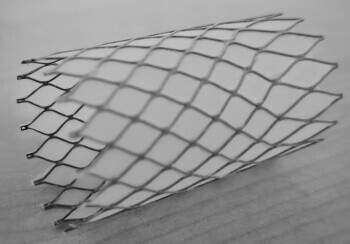

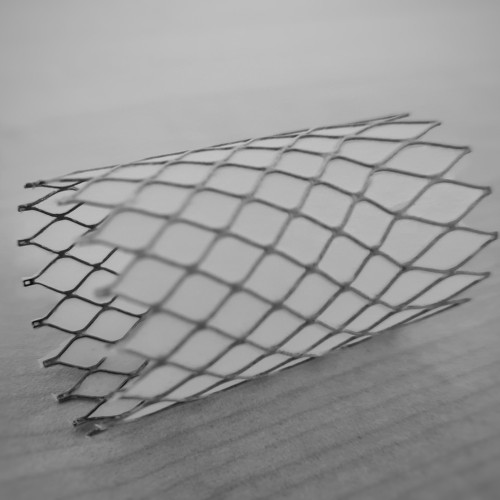

Many commercially available covered stents use sutures to stitch a polymer or fabric cover to the usually metallic structural core.

“This comes with some drawbacks”, explains Dr Moisley. “The suturing is time-consuming and expensive. It creates weak points, roughness, and protruding barbs within the stent structure. We have some of the world’s best electrospinning engineers at our company, so we decided to see if electrospinning might offer a better solution.”

It’s easy to see why so many people are desiring electrospun materials in their medical devices. When polymers are formed into micro or nano-fibres, they can exhibit very different mechanical properties compared to the same polymer in bulk. This means that far more polymers can be made soft and flexible enough for use in the human body. Not only that, but the porosity of three-dimensional scaffolds can be tailored to allow or repel cell infiltration, as required. The porosity can also be altered to affect the degradation rate of bioresorbable polymers.

“It’s the versatility of electrospinning which gives it its fantastic capabilities”.

The obvious benefits of electrospun materials have led many others to attempt direct coating of stents before.

“The tricky part has never been electrospinning onto stents,” says Dr Moisley, “That’s easy. The tricky part is making it stick.”

Adhering the structural frame to the polymer cover with enough resilience to prevent tears during crimping and catheter insertion has been the focus of her research for the last year.

“It’s been a tough problem to overcome, and it’s taken a huge amount of collective effort and expertise to face down. But I’m confident in saying that we’ve cracked it! Over the last 12 months we’ve produced prototypes for all kinds of biomedical applications from head to toe, using polyurethanes, polycaprolactones, all kinds of things”.

The Electrospinning Company has developed single layer coatings which bind to nitinol, steel, and PEEK stents, as well as bilayer “sandwich” structures which can encapsulate any material fully in a microfibrous textile.

“We want to get the word out there to everyone who works in our field – this can be done! It can be done at scale, in fully ISO certified cleanroom conditions, and it’s going to be game-changing for the industry. We have experience bringing a product all the way from prototype, to validation, to manufacture, and we’re bringing this experience to the field of sutureless stent coatings”.

If you would like to discover more about *The Electrospinning Company, contact one of their representatives HERE