Stent Coating – Dispensing application with Ciposa

posted 6th February 2023

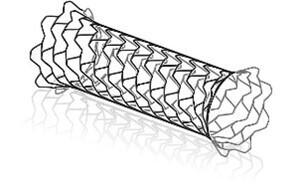

The first stents were bare metal stents (BMS) and despite improvements on the design, material and introduction techniques, BMS were facing high in-stent restenosis, which occurred in 10-30% of all stents. Restenosis is the term used when an “unblocked” vessel is “blocked” again after the procedure, usually within the first year.

The introduction of drug-eluting stents (DES) in the early 2000’s was to address the issue of restenosis. A polymer and a drug is applied to the stent strut that will help reducing the rates of repeat revascularization. The polymer, attached to the drug, serves as a barrier so the drug can be released over a period of time, generally months.

DES or third generation stents relies on manufacturing methods like ultrasonic spray coating, dipping, air brush and deposition on the stent struts. The challenges that stent manufacturers are facing are complex because the solution must be applied with accuracy, repeatability and homogeneity. Furthermore, the process must be perfectly controlled to meet medical standards.

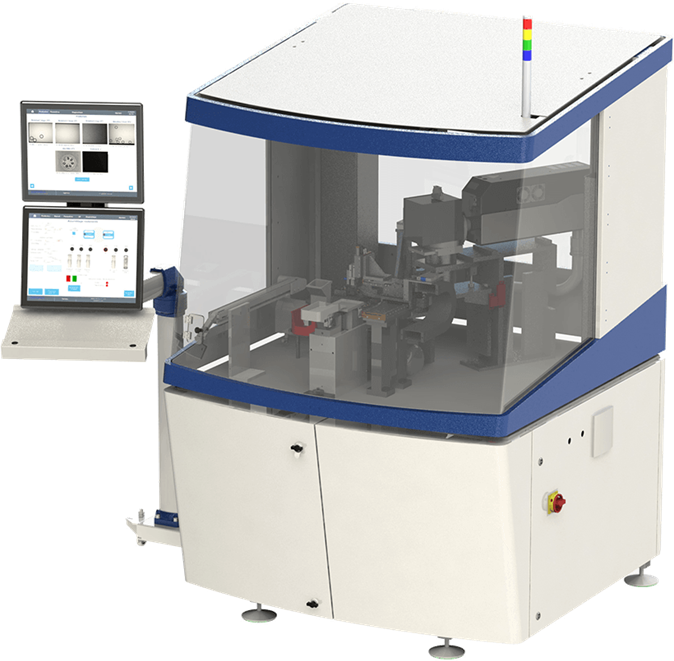

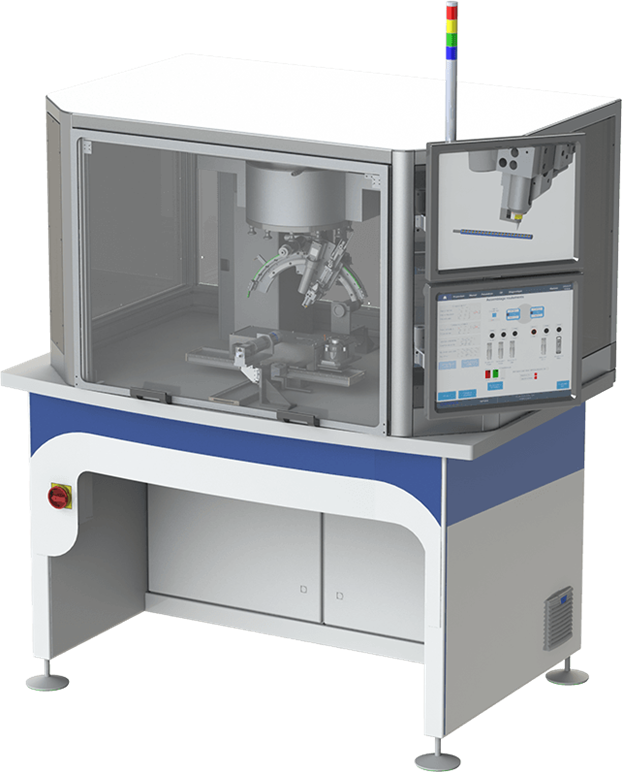

II. CIPSOA MICRO-DISPENSING STENT COATING

Ciposa, with its micro-dispensing competence center based in Switzerland, has gained a lot of experience and has provided innovative solutions for industry leaders. Ciposa uses its scalable center to conduct feasibility studies and research on behalf of its clients.

In order to have a reliable process, several parameters must be controlled, such as:

- Process repeatability

- Solution homogeneity variability along stent struts

- The influence of variations due to external physical elements like temperature or humidity

- Pressure

- Geometry of stents, struts thickness and section

- Cleaning cycles and system purges

- Actual operating life of the solution

- Effects of sedimentation

- Parameters affecting the quantity deposited

To meet such standards and to address these challenges, Ciposa relies on its expertise in micro-engineering automation solutions. The gantry is a very important element, the design and material choice determine its rigidity. A micro-dispensing head is mounted on a multi-axis gantry to achieve accurate deposition of the solution. The tolerances associated with complex geometry of stents are controlled before the process starts, using Ciposa’s knowhow in vision inspection.

A camera is dedicated to the system auto-calibration. The needle space reference is recorded for in-process inspection and corrections, making it possible to change the needles/solutions without manually off setting the machine parameters.

Key features

- Fully automated – AS.Med machine

- Semi Automated - Smart-Bench

- Needle deposition accuracy: ± 10 µm

- Final positioning repeatability on all axes: ≤ ±10 μm

- Minimum volume: 1.0 nL

- Repeatability: ± 5%

- Cycle time per drop: 2 seconds

Vision Inspection

- Critical dimensions

- Global shape (Detection & Rejection of curved components)

- Holes or Gaps in the stent mesh

The products and automated solutions are designed for the customer and its applications therefore each project is unique. Stent coating is complex and manufacturers are not only looking for process capabilities, but also for productivity and performances. More complex stents are designed and news drugs arrive on the market with different properties that lead to constant improvements and responsiveness for automation and vision inspection methods.

Ciposa will be represented on stand 21 by Mastrini Machine and Services at Medical Technology UK 2023.

The entire exhibition and Learning Programmes is FREE to attend.

REGISTER HERE