Rapid Prototyping and 3D Printing Technologies used to Develop Test Parts for Performance Testing

posted 23rd February 2022

Neucin Design Ltd have extensive experience in the design and development of inhaler devices and over the past few years have executed numerous tests as part of device performance testing and characterisation using industry standard testing equipment in conjunction with their own in-house bespoke testing apparatus.

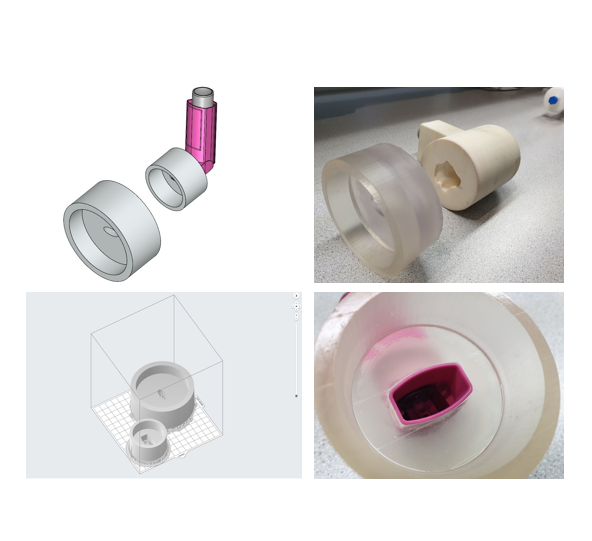

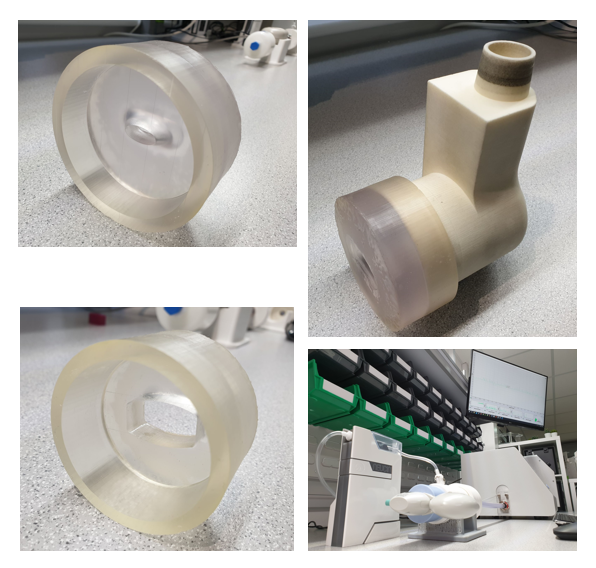

When testing inhaler’s the mouthpiece adaptor is the critical interface between the device and the test apparatus. Its interaction with the device is crucial for not only ensuring a suitable seal but is essential for gaining consistent, reliable, and repeatable test results.

Recently, Neucin collaborated with the team at Nanopharm Ltd, an Aptar Pharma Company to produce a series of custom mouthpiece adaptors utilising their internal rapid prototyping and 3D printing technologies to support their testing requirements.

Taking this approach is extremely versatile as it allows for the design and manufacture of standard and custom mouthpiece adaptors in a few simple steps.

This combined with advancements in additive manufacturing material suitability means a mouthpiece adaptor with similar material properties, shore hardness, robustness, sealing capability and accuracy can be achieved as well as long term repeated use without reduced performance.

There are some significant advantages to taking this approach.

➡️ Short lead time, typically 4 days.

➡️ Reduced cost.

➡️ No tooling costs.

➡️ Can be tested and evaluated in-house prior to supply.

➡️ Easy to update and customise the design without implication on the tooling.

➡️ Easy to reproduce or produce multiples at the same time.

➡️ No design constraints and therefore more unusual and complex shapes can be achieved for emerging device designs or to suit non-standard test set-ups.

So far, the test results and feedback from the team at Nanopharm have been very positive, and Neucin will continue to optimise the design and in-house manufacturing process to ensure the most accurate and suitable mouthpiece adaptor designs can be provided

Neucin Design Ltd will be on stand 22 at Medical Technology UK

Registration for the entire Exhibition, Learning Programme and Women in MedTech Forum is now open.

Free Parking. Free Admission

REGISTER RIGHT HERE, RIGHT NOW