Liquid Penetrant Testing - Non-Destructive Testing Solution

posted 3rd March 2024

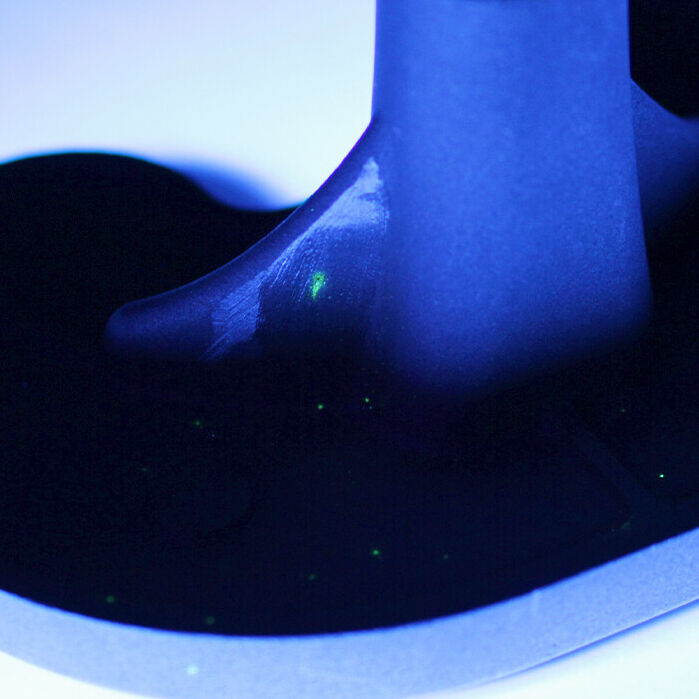

Enter the realm of Liquid Penetrant Testing, also recognised as Fluorescent Penetrant Inspection (FPI) - a widely embraced non-destructive testing (NDT) method revolutionising component inspections. Renowned in the medical and aerospace sectors, this technique excels in pinpointing surface-breaking defects with unparallelled precision.

Kemet, trailblazers in precision surface finishing, elevate FPI to new heights through their cutting-edge process control systems. These systems guarantee batch repeatability, process safety, and traceability, setting the bar for quality control and efficiency. Aligned with the ASTM E1417 FPI standard, widely adopted in medical and aerospace sectors, Kemet's FPI systems offer both standard configurations and the flexibility to seamlessly integrate automated and manual operations. This ensures a streamlined, maintainable NDT inspection process that is both efficient and economical.

Designed with integrated waste water handling and extraction systems, Kemet's FPI systems yield substantial cost savings on process chemicals, labour, and energy. From fully automated systems for airframe components, turbine blades, and medical implants to smaller manual systems catering to less critical parts, Kemet's FPI solutions strike the perfect balance between automation and manual handling, resulting in labour savings and a compact footprint. Just like their ultrasonic cleaning machines, these FPI systems are celebrated for their durability, safety, ergonomics, and user-friendliness.

Kemet doesn't offer a one-size-fits-all approach; instead, they provide a diverse range of Fluorescent Penetrant Inspection tailored to meet the unique requirements of different industries. From flexible manual roll track spray lines with a minimal footprint to fully automated roll conveyor immersion lines designed for high-capacity mass production, the company offers solutions for every application. These systems boast features like material handling, batch traceability via a data log, fully automated penetrant and developer spray, basket rotation, basket trolleys, and automatic loading/unloading conveyors.

For further details, please do not hesitate to reach out to Kemet via email at sales@kemet.co.uk or

Tel: +44 (0) 1622 755287

Kemet will be exhibiting at Medical Technology UK 2024, the UK's only event exclusively focused on the design, research, engineering and advancement of medical devices, on stand #22.